Drinking water

In the vast panorama of water purification, ensuring a safe and reliable supply of drinking water is an essential priority. In this context, SATI filters represent a solid solution to guarantee the quality and safety of water intended for human consumption.

SATI drinking water filters are designed with the aim of removing impurities, contaminants and pathogens present in raw water, thus helping to ensure that the treated water meets the highest standards of quality and safety for human consumption .

These filters have been carefully developed and tested to provide reliable and long-lasting performance in the water purification sector. Thanks to their advanced technology and solid construction, SATI filters are capable of removing a wide range of contaminants found in raw water, including sediment, organics, microbes and chemical pollutants.

The versatility of SATI filters allows the customization of filtration solutions based on the specific needs and characteristics of the raw water to be treated. This means that SATI filtration systems can be adapted and optimized to address the specific challenges of each water treatment site, ensuring effective and consistent results. SATI filtration systems are designed to offer simple and efficient maintenance, ensuring continuous operation.

This aspect is crucial to minimize downtime and maximize the operational efficiency of water purification systems. For this delicate sector, SATI relies on specific components to guarantee maximum safety and efficiency.

Among these, silicone gaskets and neutral nylon components play a fundamental role in ensuring compatibility with drinking water. In conclusion, SATI filters represent a reliable and convenient choice for the implementation of filtration systems in the field of water purification.

With their cutting-edge technology, robustness and versatility, SATI filters significantly contribute to ensuring a safe and sustainable supply of drinking water for communities, cities and industries around the world.

Our Filters

All filters can be customized according to customer needs.

Customized filtration systems are also designed.

Filtration is a fundamental step in the water purification sector, aimed at removing contaminants and impurities to make water safe for human consumption. This process occurs in several stages, each with specific technologies to eliminate various types of pollutants.

These combined processes ensure that the water is safe and of high quality for human consumption.

Location

NorwayDegree of filtration

53 µmScope

25m3/giornoWater source

Acqua di fiumeA small Norwegian municipality needs to treat and purify water to make it drinkable, so it needs a treatment plant to provide drinking water to its inhabitants.

This drinking water facility has three groundwater wells. Prior to the installation of the container, the customer had encountered particle issues in the raw water, which they wanted removed prior to subsequent water treatment.

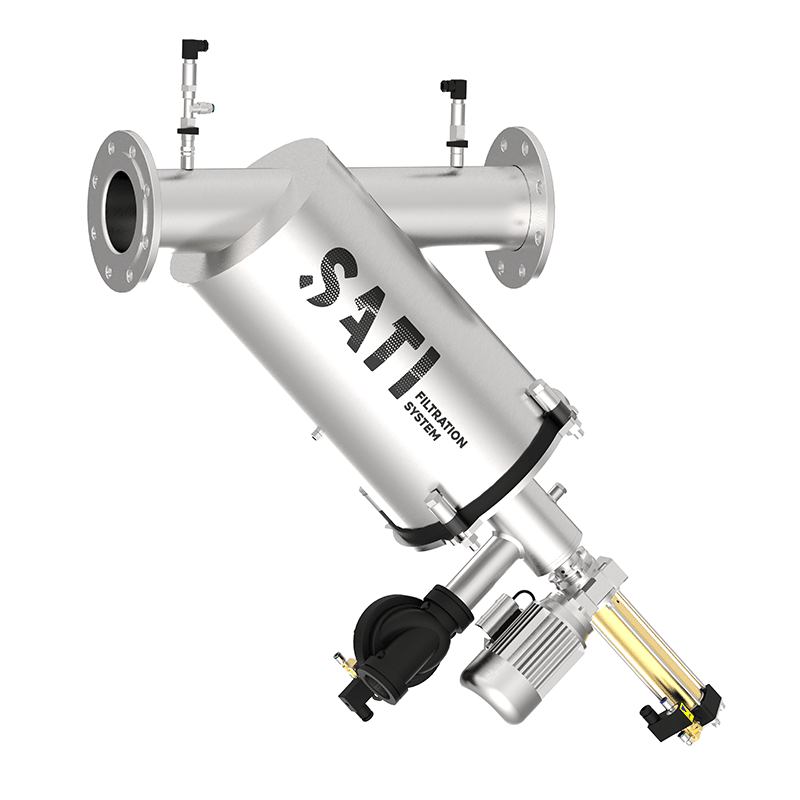

To solve this problem, several filtration steps were installed: a VTO filter from SATI as pre-filtration, two UV filter units, an emergency power unit, a dehumidifier. The system is capable of producing 25 m³ of treated water per day. The VTO automatic filter was chosen to remove particles present in groundwater.

The VTO filter is equipped with suction and counterflow nozzles during the washing phase, the particles are sucked up and removed efficiently, guaranteeing an excellent pre-filtration step. Furthermore, the VTO automatic filter, thanks to the “NO-STOP-FLOW” system, ensures a continuous flow even during the washing phase, avoiding interruptions in the filtrate. This solution was motivated by several factors.

First of all, the ease of installation made it possible to quickly set up the system without the need for complex or expensive interventions. Furthermore, the compact design allowed for significant space savings. Another element was the simplicity of maintenance, which significantly reduces the time and resources required for the continuous operation of the plant.

This is very important considering that the system is located in a municipality with little available staff.

The pdf document of this case history

is reserved for registered users.

Contact us

HEADQUARTERS

M.Galli Street, 116

47522 Cesena (FC) – Italy

CALL US

T. +39 0547 660307

UNI EN ISO 9001:2015 certified company