Automotive sector

In the automotive industry, water filtration is important for several purposes, including the treatment of water used in manufacturing processes and the use of water filtration systems for the vehicles themselves.

Automotive factories use large amounts of water for various purposes, such as production, machinery cooling and cleaning. It is essential that water be filtered to remove solid impurities, harmful chemicals, and bacteria to ensure the quality of production processes and protect production facilities.

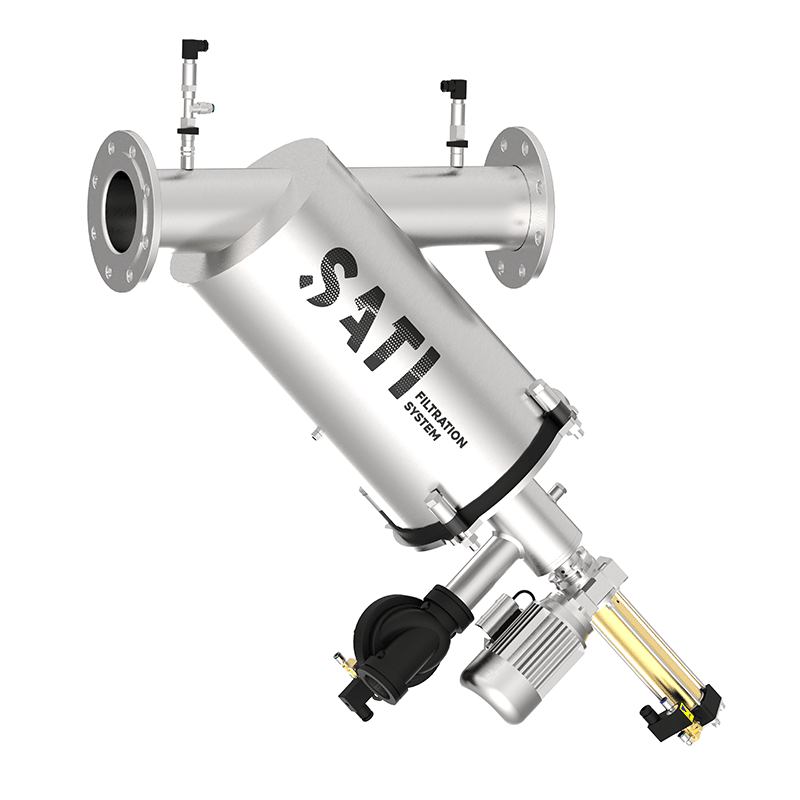

This is where SATI filters come in for the filtration stage and the subsequent recovery of filtered water through the use of special filtration systems. Filtered water can be used again in various production processes in automotive factories, such as in parts washing, painting, and other operations that require clean water, all of which provide numerous benefits in terms of sustainability, efficiency, and cost reduction.

SATI filtration systems can be integrated into the production processes of automotive factories to remove solid impurities, oils, greases and other contaminants from water used in manufacturing processes. This allows treated water to be reused, thereby reducing the overall consumption of fresh water and the costs associated with water resource management.

SATI filters then, can be used to filter water within the cooling systems of machinery and vehicles, helping to prevent the accumulation of sediment and contaminants in the circuits and maintaining the efficiency of cooling systems, without compromising the performance or life of components.

The use of SATI filtration systems in the automotive industry to recover filtered water offers numerous benefits, including reducing operating costs, saving water resources and reducing the environmental impact of production activities. By integrating advanced filtration solutions with sustainable water management practices, automotive companies can achieve significant benefits in both economic and environmental terms.

Our Filters

All filters can be customized according to customer needs.

Customized filtration systems are also designed.

Contact us

HEADQUARTERS

Via M.Galli, 116

47522 Cesena (FC) – Italy

CALL US

T. +39 0547 660307

UNI EN ISO 9001:2015 certified company