Cooling water

Cooling towers play an essential role in many industrial plants, enabling the cooling of water used in production processes through evaporation. However, to ensure optimal operation of cooling towers and preserve the efficiency of industrial processes, it is essential to ensure the quality of the water used. To this end, SATI offers easy-to-install filtration solutions that can bring significant benefits to plants, allowing for lower operating costs.

The filtration solutions offered by SATI are designed to remove impurities, sediments, and contaminants in the water that could impair the proper operation of cooling towers and cause damage to equipment. These filtration systems are easy to install and can be integrated with existing plant infrastructure without requiring significant structural changes.

Once installed, SATI filtration systems work constantly to keep water clean and free of impurities. This helps prevent clogging and plant damage, extending the life of cooling towers and reducing the need for corrective maintenance. In addition, better water quality can enable greater energy efficiency by reducing energy consumption associated with cooling tower operation.

With SATI filters, industrial plants can benefit from increased operational reliability, reduced maintenance requirements and better overall efficiency. This results in increased productivity and significant savings in operating costs in the long term.

The implementation of filtration systems offered by SATI is a worthwhile investment for industrial plants, enabling them to ensure the quality of water used in cooling towers and achieve tangible benefits in terms of operational efficiency and cost savings.

Our Filters

All filters can be customized according to customer needs.

Customized filtration systems are also designed.

Cooling towers are devices used to remove heat generated by industrial processes. These towers use the principle of water evaporation to disperse heat into the ambient air. Hot water is flowed through a filling system into the tower, where it meets a flow of air. The cooler air causes the water to evaporate, absorbing heat and cooling the water itself. Cooling towers are therefore essential for keeping industrial process temperatures under control and preventing equipment from overheating.

Water filtration is equally important to ensure that water used in cooling towers and industrial processes is clean and free of impurities that could damage equipment or compromise product quality.

Location

ItalyDegree of filtration

50 µmScope

20 m3/hTreated water

Process waterCooling towers in a famous Italian factory are needed to prevent water pollutants from clogging internal components and to ensure the most efficient water/air heat exchange process for maximum productivity.

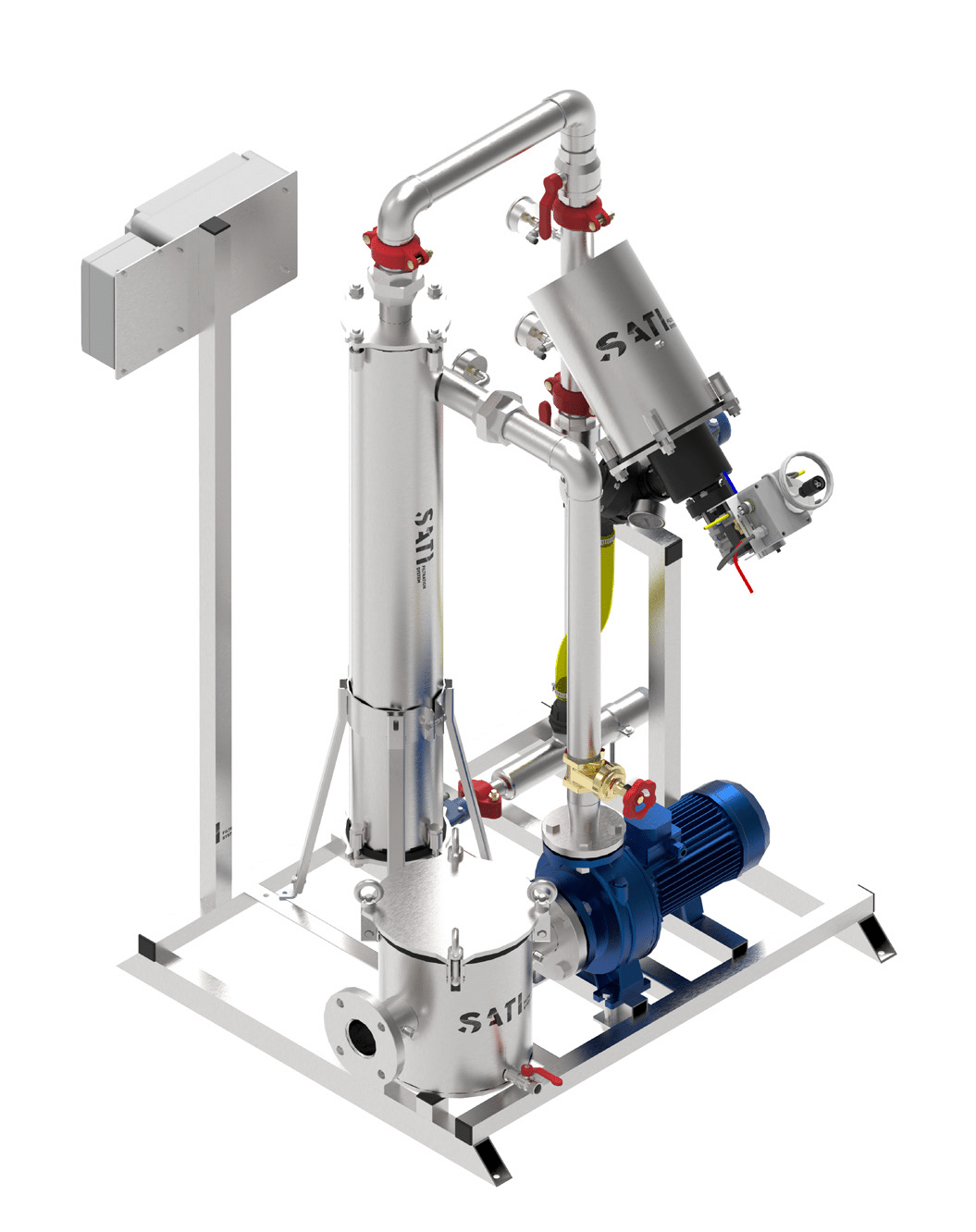

In this successful case, after close collaboration between the company’s project team and our engineering department, a CTFS-VXAF automatic filtration skid consisting of a Vortex hydrocyclonic filter and a Rotor filter was selected; this combination provides a full range of filtration from sand to collodial particles.

The skid is integrated with a pump, which is protected by the Mini basket filter, manifolds, and a plug-and-play control unit, ready to be installed. The adopted solution ensured fast installation time and provides improved productivity and reduced maintenance operations with a direct impact on efficiency, cost and energy savings.

The pdf document of this case history

is reserved for registered users.

Contact us

HEADQUARTERS

Via M.Galli, 116

47522 Cesena (FC) – Italy

CALL US

T. +39 0547 660307

UNI EN ISO 9001:2015 certified company