Mining sector

Water filtration in the mining sector is crucial to ensuring the safety and sustainability of mining and processing operations.

SATI filters and filtration systems represent a fundamental solution in this sector, to guarantee the quality and safety of water resources used in extraction and manufacturing processes. These systems are designed to address the unique challenges that characterize the mining environment, which is why SATI filters offer a number of significant advantages:

- Efficiency in removing impurities: SATI filtration systems are designed to efficiently remove suspended particles and contaminants present in water, ensuring it is suitable for mining operations without compromising the quality of the process.

- Strength and durability: SATI filters are constructed of strong, durable materials that can withstand the harsh environmental conditions typical of the mining environment, such as extreme temperatures, high pressures and aggressive chemicals.

- Ease of maintenance: SATI filtration systems are designed to require minimal maintenance, allowing mining operations to focus on core activities without interruptions due to frequent component failures or replacements.

- Adaptability: SATI filters can be customized to meet the specific needs and dimensions of mining facilities, ensuring effective management of water resources based on individual conditions and current environmental regulations.

Implementing SATI filtration systems in the mining industry helps ensure regulatory compliance, protect the surrounding environment and improve the sustainability of mining operations. Furthermore, better management of water resources reduces the overall environmental impact of the mining industry and promotes greater social and environmental responsibility.

SATI filters and filtration systems offer reliable and efficient solutions for the mining sector, helping to preserve water quality and promote sustainable practices in the extraction and processing of natural resources.

Our Filters

All filters can be customized according to customer needs.

Customized filtration systems are also designed.

Water filtration in the mining industry is an essential process to ensure that the water used in mining and processing operations is safe and free of harmful contaminants. In mines, water is used for a variety of purposes, including transporting ore, cooling machinery, and mining.

However, water used by mines can be contaminated from various sources, including sediment, heavy metals and chemicals used in mining processes. Water filtration in the mining industry involves the use of advanced systems that can effectively remove these impurities, ensuring that the water is safe for use and complies with environmental regulations.

Location

AustraliaDegree of filtration

50 µmScope

2.070 m3/hTreated water

Process waterA major Australian mining company needed to remove all particles larger than 50 microns from the mineral processing waters before sending them to a Middings Teeter classifier.

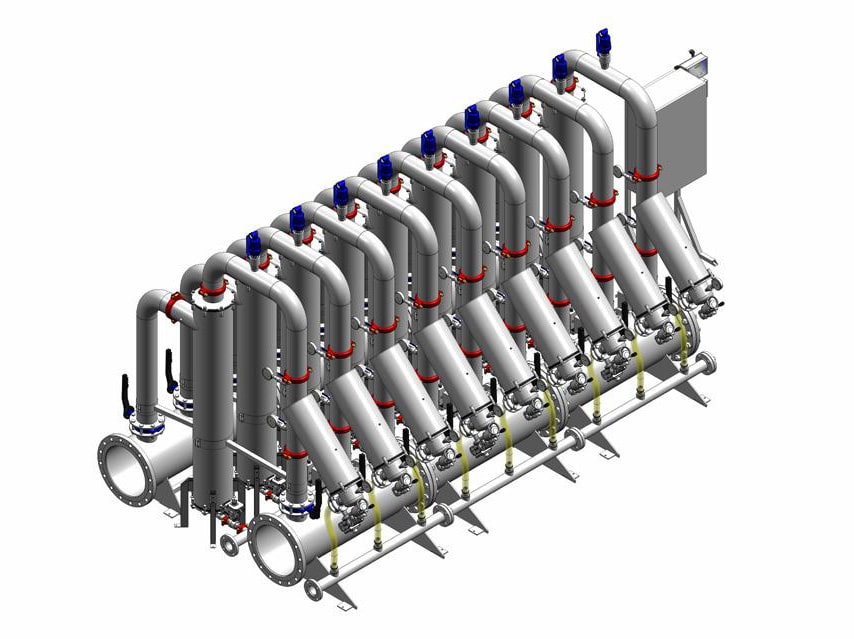

To manage the presence of solids of different sizes, a two-stage filtration system was adopted. The first stage consists of nine Vortex centrifugal separators, while the second stage includes nine Rotor filters, with a filtration rating of 50 microns. This system has been pre-assembled in a single filtration battery to ensure optimal efficiency. The entire system can handle the required flow rate 24 hours a day. The waste water from the Vortex separators and the Rotor filter cleaning cycles is collected and disposed of through a special outlet.

Thanks to the implementation of the SATI filtration system, water waste is reduced to a minimum and clean and safe water is always guaranteed.

The pdf document of this case history

is reserved for registered users.

Contact us

HEADQUARTERS

M.Galli Street, 116

47522 Cesena (FC) – Italy

CALL US

T. +39 0547 660307

UNI EN ISO 9001:2015 certified company