Paper sector

In the paper industry, the use of SATI filtration systems and filters is vital to ensure the quality of water used in production processes and to protect equipment from the damaging effects of impurities in the water. SATI offers a wide range of filtration solutions specifically designed to meet the specific needs of the paper industry, ensuring effective cleaning and protection of the water used.

SATI filtration systems for the paper industry are designed to remove particles, sediment, organics and other impurities in water, ensuring clean, contaminant-free water for papermaking processes. These systems are equipped with high-quality filters that provide effective filtration while maintaining a steady flow of water through the system.

SATI filters are available in several configurations, including self-cleaning filters, mesh filters, basket filters, and bag filters, each designed to address specific filtration needs in the paper industry. Self-cleaning filters, for example, are ideal for removing particles of varying sizes, ensuring continuous cleaning without interruption in plant operations, and can communicate with other machines via new automation systems.

Because of their reliability and efficiency, SATI’s filtration systems and filters enable paper companies to achieve better finished product quality while reducing operating costs and minimizing environmental impact. Investing in SATI filtration solutions is therefore a strategic choice for paper companies in terms of efficiency, product quality and environmental sustainability.

Our Filters

All filters can be customized according to customer needs.

Customized filtration systems are also designed.

Water within the paper industry plays a key role in multiple stages of the papermaking process. It is mainly used as an essential component in the formation of the paper sheet itself, in the preparation of raw materials, such as wood or cellulose, and in the mixing of chemicals needed to achieve the desired consistency of paper pulp.

It is important to note that the water used in this industry must be of high quality and free of impurities that could compromise the quality of the finished product. Therefore, water treatment and filtration systems are essential to ensure that water used in production processes is adequately clean and safe for use.

Location

ItalyDegree of filtration

120 µmScope

50 m3/hTreated water

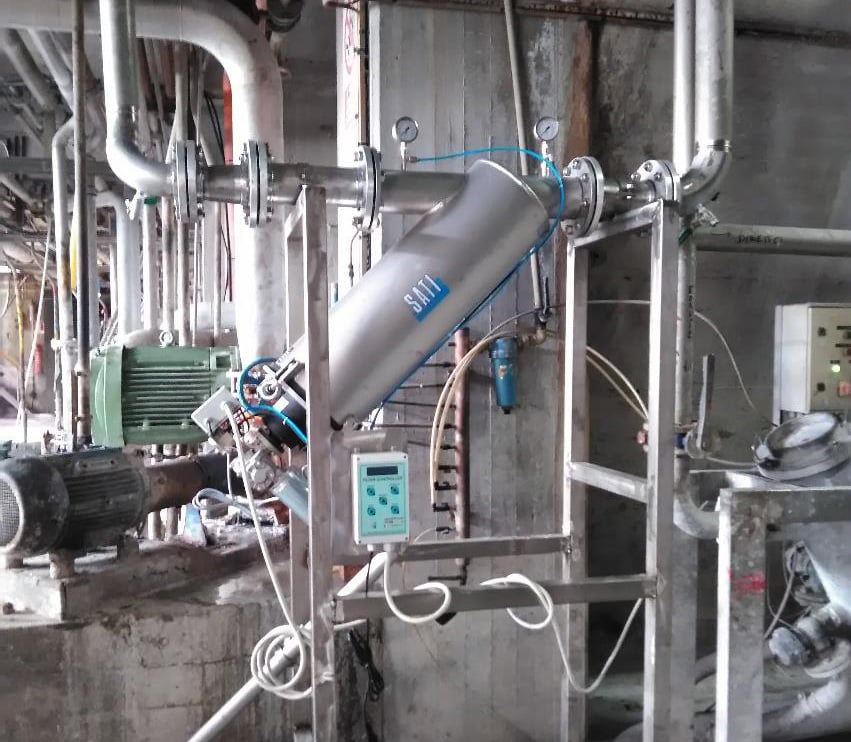

Technical waterWithin a large paper mill in Tuscany, there was a need to filter technical water from processing to cool the seals of production machines. The water used for this process, coming from the papermaking process, had cellulose residues in it that frequently clogged the manual filtration devices present. The filtration process is critical for this type of application because any clogging of the pipelines or any paper particles (or derivatives) deposited on the seals would cause them to fail resulting in lost production and repair costs.

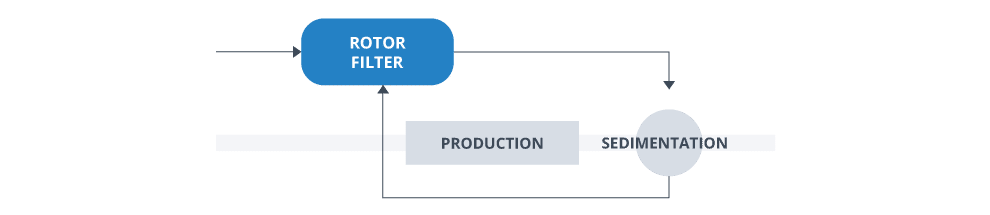

In order to properly filter water from papermaking processes, it was necessary to remove cellulose particles, thus colloidal and small, of a filtration degree of 120μm. Particles deposited on the filter cartridge have a colloidal confirmation and tend to disintegrate on the surface of the cartridge when placed under high pressures. We therefore opted for a Rotor filter with suction skids, which are excellent for the removal of colloidal particles.

To prevent the particles from disintegrating on the filter cartridge, we have provided a “three-dimensional” type of filtration mesh, this type of filter element having a three-dimensional type texture, prevents the particles from disintegrating or remaining anchored to the cloth during regeneration. The installation of the Rotor filter solved the company’s problem and ensured the functionality of the mill’s entire production plant at all times.

The pdf document of this case history

is reserved for registered users.

Contact us

HEADQUARTERS

Via M.Galli, 116

47522 Cesena (FC) – Italy

CALL US

T. +39 0547 660307

UNI EN ISO 9001:2015 certified company