Plastic and Fabrics

Water filtration represents a crucial element in both the plastic and textile sectors, ensuring the quality and purity of the water used in production processes. In the production of plastic, water is used for cooling molds and cleaning equipment, while in the textile sector it is essential for washing fibres, dyeing and finishing fabrics. The removal of particles, sediments and contaminants is essential to maintain the quality of the final product and ensure the efficiency of the machinery.

SATI distinguishes itself by providing filtration systems specifically designed for both of these industrial sectors. In the context of the circular economy, where plastic recycling plays a key role in reducing environmental impact and promoting resource sustainability, the self-cleaning, semi-automatic or manual filters offered by SATI are essential for eliminating impurities and contaminants, guaranteeing quality and the purity of recycled materials.

In plastic production processes, cooling water can be recycled through SATI filtering and recycling systems, reducing fresh water consumption.

In the textile sector, SATI filters are used in the treatment and reuse of process water, thus reducing the withdrawal of fresh water and related operating costs. These practices not only generate significant economic savings, but also help mitigate environmental impact by reducing the quantities of wastewater discharged into the environment and promoting responsible management of water resources.

The vast range of filters offered by SATI, capable of adapting to the specific needs of each sector, allows companies to benefit from customized filtration solutions, guaranteeing the highest quality of the water used in production processes. This translates into greater operational efficiency, less need for maintenance and an overall improvement in the quality of finished products, contributing to the success and growth of the company.

Our Filters

All filters can be customized according to customer needs.

Customized filtration systems are also designed.

Plastic recycling is a fundamental component of the waste management process, which involves a series of operations aimed at transforming plastic waste into new usable materials.

This specific sector of recycling requires the collection, separation and processing of plastic waste, followed by cleaning, crushing and melting operations. Through these processes, plastic materials are transformed into granular or pellet form, ready to be reintegrated into production processes.

Recycling plastic not only reduces the amount of waste going to landfill, but also the reliance on virgin raw materials and the environmental impact associated with their extraction and production. Furthermore, it helps preserve natural resources and mitigate pollution caused by plastic.

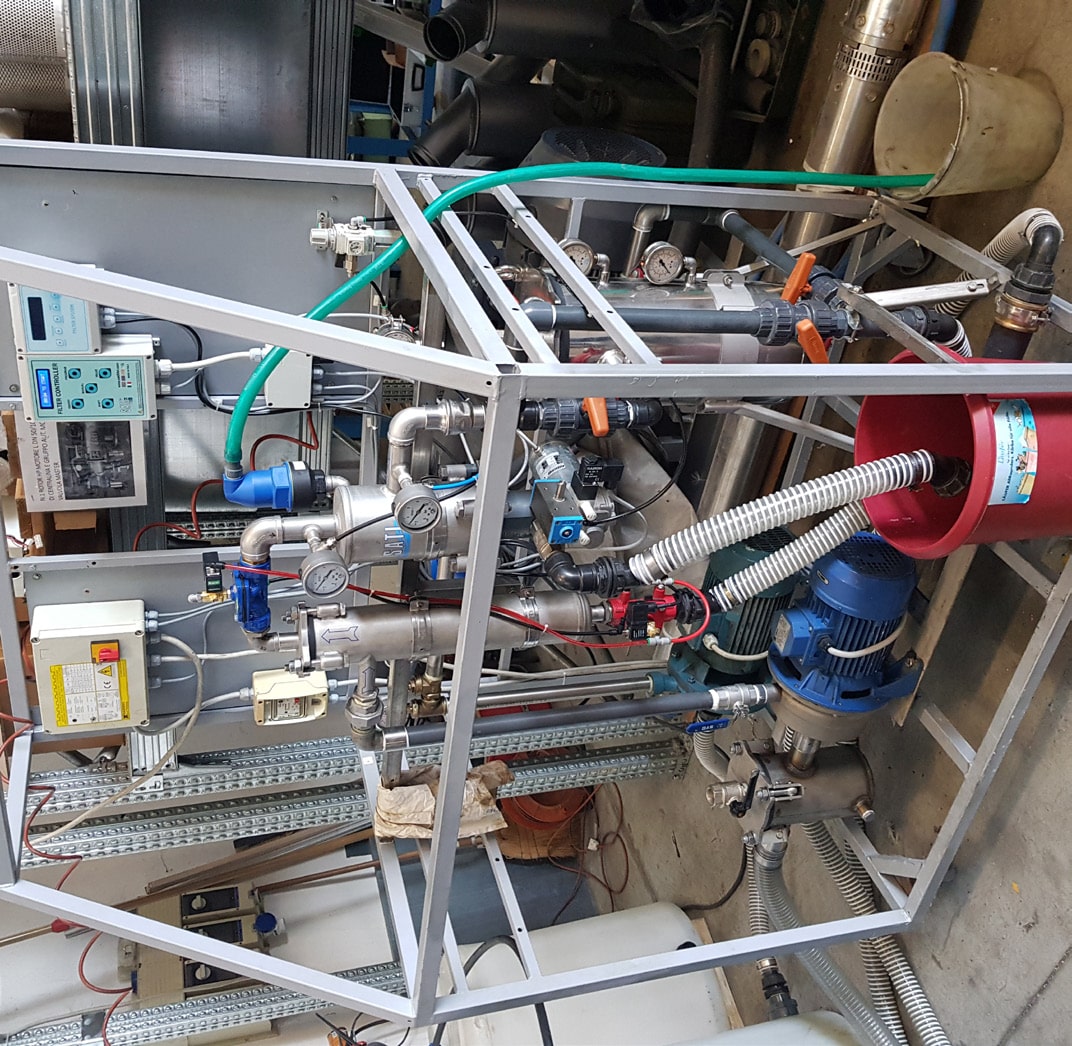

Location

North ItalyDegree of filtration

100 µmScope

20 m3/hTreated water

Process waterPlastic recycling is a specific sector of waste recycling, which involves a set of operations, at the end of which a new plastic material is obtained to be reintroduced into the production processes. In the recycling of plastic materials, large quantities of water are used for the washing phase of the processed material.

Our filtration system has allowed us to completely reuse the washing water and keep the entire system clean. Furthermore, this solution allowed the customer to save money, given that in the past public water was used during this process.

The pdf document of this case history

is reserved for registered users.

Contact us

HEADQUARTERS

Via M.Galli, 116

47522 Cesena (FC) – Italy

CALL US

T. +39 0547 660307

UNI EN ISO 9001:2015 certified company