Energy production

Power generation is an area in which water plays an essential role, both for cooling power plants and for hydropower generation. In both cases, it is important to ensure that the water used is clean and free of contaminants to ensure proper operation of the plants and reduce environmental impact.

SATI filtration systems are widely used in the energy sector to treat water used in power generation processes.

In the case of thermal power plants, SATI filters are used to remove impurities in the cooling water, ensuring that the cooling system operates efficiently and that the water discharged into the environment is safe for aquatic life.

In the case of hydropower, SATI filtration systems are used to treat water from reservoirs and rivers, ensuring that it is free of debris and contaminants that could damage turbines and other hydropower equipment.

In both cases, the use of SATI’s filtration systems helps ensure efficient operation of power plants, reducing operating costs and improving the environmental sustainability of energy operations.

In fact, SATI’s advanced filters and filtration systems help optimize the operational efficiency of power plants, reducing downtime due to water quality issues and improving the overall sustainability of power operations.

In conclusion, water is a vital component in energy production, and the use of SATI filtration systems helps ensure that this precious resource is used efficiently, safely and sustainably.

Our Filters

All filters can be customized according to customer needs.

Customized filtration systems are also designed.

In thermal power plants, water is used to cool steam generators and turbines, ensuring the proper operation of the plants. However, this process generates large amounts of warm water that must be treated before being released into the environment to avoid negative impacts on aquatic fauna and flora.

In hydroelectric power plants, water is the primary source of energy, used to turn the turbines that generate electricity. This method of energy production is considered more sustainable than fossil sources, but still requires responsible management of water resources to minimize environmental and social impacts.

In both cases, efficient water management is critical to ensure the efficiency and sustainability of energy production.

Location

ItalyDegree of filtration

25 µmScope

9 m3/hTreated water

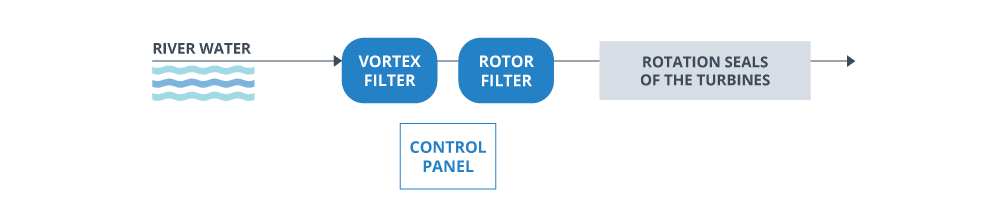

Cooling waterWithin a large hydroelectric power plant, there was a need to cool the rotational seals of the turbines. The water used for this process was from the river on which the turbine was installed.

This type of water carried with it, depending also on the weather conditions, different types of suspended solids, which created disruptions to the pipelines and the seals themselves. The types of solids that were found inside the pipeline were algae, sand and organic materials.

In order to properly filter the water coming from the river, two steps of filtration were provided, a coarse one consisting of a Vortex filter, which separates all large particles (with specific gravity higher than water) and sands up to 75 μm, then Rotor filters were installed, which go, with a filtration degree of 25 μm, to separate all colloidal particles.

Since this is an unmanned hydroelectric power plant, an electrical control panel was provided that can communicate via the Modbus system with the supervision and communication systems in the power plant so that any anomalies can be reported immediately and the operator can go to the site promptly.

The pdf document of this case history

is reserved for registered users.

Contact us

HEADQUARTERS

Via M.Galli, 116

47522 Cesena (FC) – Italy

CALL US

T. +39 0547 660307

UNI EN ISO 9001:2015 certified company